Continuing Bonding and Grounding Conductors - What the Code Really Says

Introduction

Proper bonding and grounding of electrical systems is crucial for safety. However, the specific requirements around continuing bonding and grounding conductors as stated in the National Electrical Code (NEC) can be confusing. In this article, I will break down the key points and clarify what the code really says about continuing bonding and grounding conductors.

What are Bonding and Grounding Conductors?

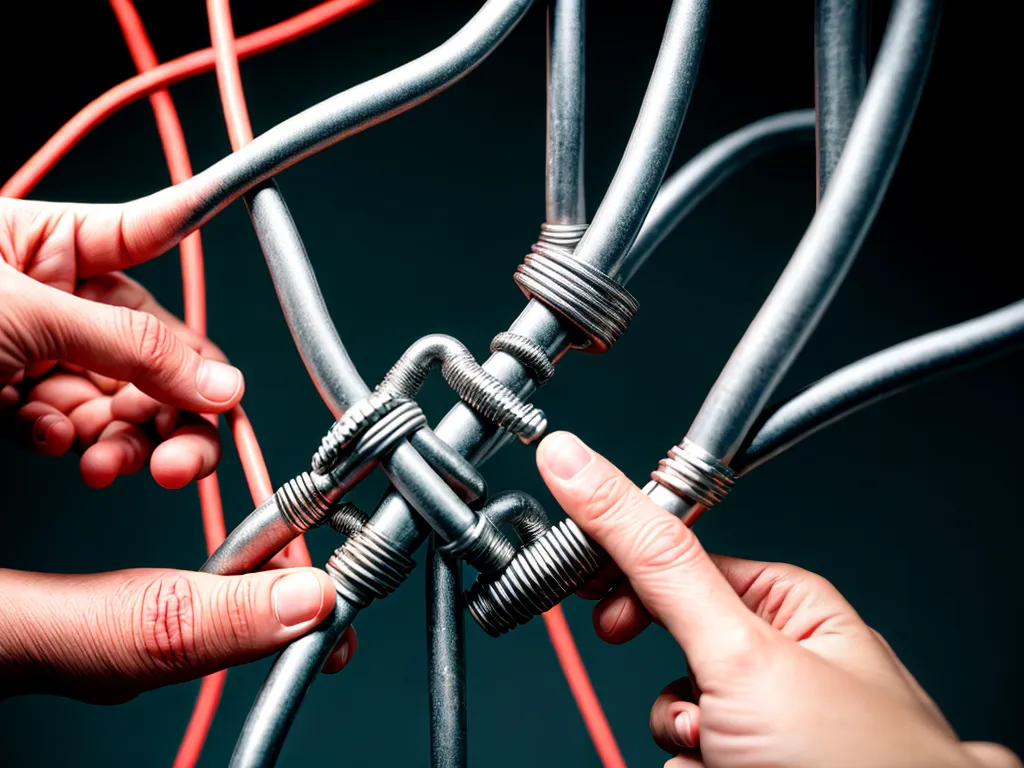

Bonding conductors provide electrical connectivity between metal parts to maintain equal voltage between the parts. This equalizes the voltage to prevent current flow, reducing the risk of shock.

Grounding conductors provide a low-impedance path to the ground to safely dissipate fault current and lightning strikes without causing damage or injury.

Bonding and grounding work together to protect people and equipment.

Continuing vs Supplementary Bonding and Grounding Conductors

The NEC makes a distinction between continuing and supplementary bonding and grounding conductors:

-

Continuing bonding and grounding conductors extend the bonding and grounding path without any disconnects.

-

Supplementary bonding and grounding conductors provide additional bonding and grounding for parts of the system likely to become energized, like pools and spas.

The key difference is that continuing conductors provide an unbroken path, while supplementary conductors enhance bonding and grounding in specific locations.

Requirements for Continuing Bonding and Grounding Conductors

The NEC has specific rules around continuing bonding and grounding conductors:

Continuity

- Continuing bonding and grounding conductors must be installed to ensure good continuity without any disconnects (NEC 250.96). Any connections must be made using irreversible compression connectors or exothermic welding.

Wire and Conduit Sizing

-

Continuing bonding and grounding conductors must be sized according to NEC 250.122. The conductors must be no smaller than the largest ungrounded conductor serving the equipment.

-

The metal conduit containing continuing bonding and grounding conductors cannot be used as the sole equipment grounding conductor (NEC 250.118).

Isolation

- Continuing bonding and grounding conductors routed through metal conduit must be isolated from the conduit. The conductors must be insulated or the conduit fittings isolating the conductors must be used (NEC 250.96(B)).

Separate from Grounded Conductors

- Continuing grounding electrode conductors cannot be run in the same conduit as uninsulated grounded service conductors (NEC 250.64(E)).

Common Misconceptions

Some common misconceptions about continuing bonding and grounding conductors include:

-

Thinking any bonding or grounding conductor is "continuing": Only conductors that extend the path without disconnects are considered continuing. Supplementary conductors are not the same.

-

Assuming the conduit can serve as the grounding conductor: The conduit is not enough - insulated continuing grounding conductors must be run through the conduit as well.

-

Not isolating continuing grounding conductors from metal conduit: Failing to isolate the conductor can energize the conduit and eliminate the grounding path.

Conclusion

The key points to remember about continuing bonding and grounding conductors are:

-

They must provide an unbroken grounding path without disconnects.

-

They must be sized properly based on the largest ungrounded conductor.

-

They must be isolated from conduits containing them.

-

They cannot share conduits with uninsulated grounded service conductors.

Following these code requirements ensures proper bonding and grounding to protect people and equipment. Let me know if you have any other questions!