Introduction

As an industrial facility manager, ensuring electrical safety should be one of my top priorities. Electrical hazards like arc flashes can cause severe injuries and even death if proper safety precautions are not followed. However, arc-flash requirements can sometimes seem obscure and complicated to implement.

In this guide, I aim to explain in simple terms what arc flashes are, why they occur, how to analyze arc-flash risks, and most importantly - how to control these risks by following the latest NFPA 70E arc-flash requirements. My goal is to provide facility managers with an extensive and practical understanding of managing arc-flash hazards.

What is an Arc Flash?

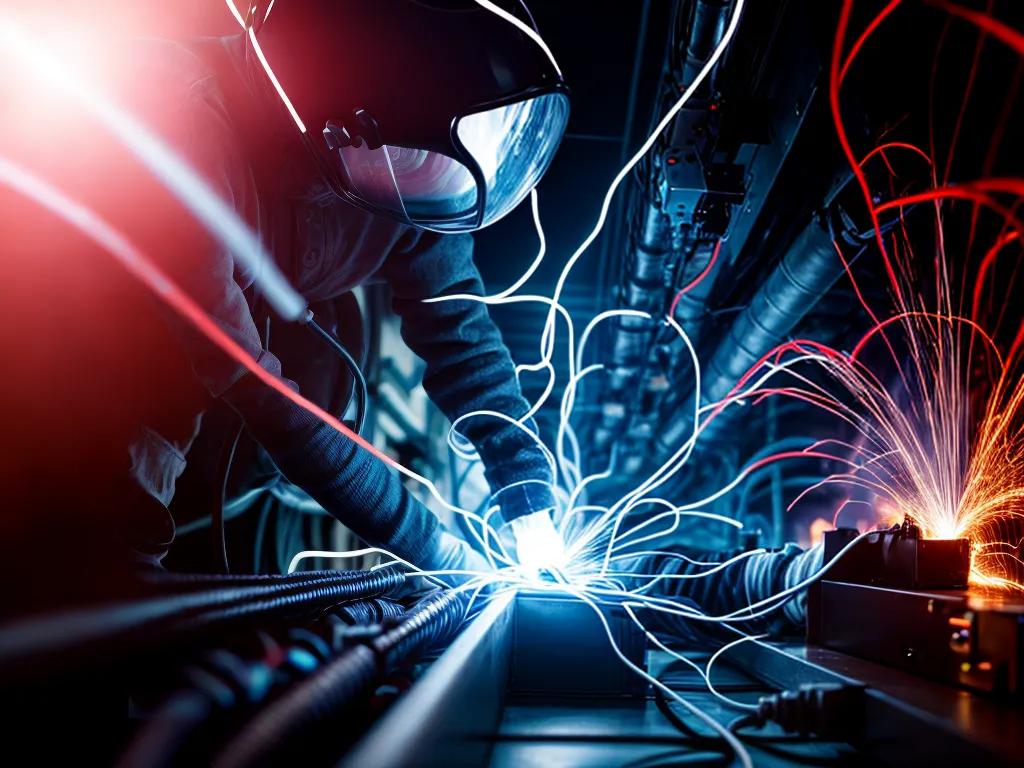

An arc flash is an explosive release of energy that occurs when an electric current passes through the air between conductors. It causes intense heat, a loud noise, and a blinding light.

The air gets rapidly heated by the arc to around 35,000°F - which is 4x hotter than the surface of the sun! This leads to severe burn injuries from the heat exposure. The resulting pressure waves can also damage eardrums and cause internal injuries.

Why Do Arc Flashes Occur?

Arc flashes usually occur due to some type of system failure like:

- Accidental contact between energized conductors, or between an energized conductor and ground. This can happen during maintenance activities.

- Buildup of conductive dust or corrosion leading to short circuiting.

- Unintentional energizing of equipment undergoing maintenance.

- Failure of insulation between conductors.

- Dropping of tools or other conductive items onto energized parts.

I must ensure proper electrical safety protocols are in place to prevent such system failures and avoid arc flash incidents.

How to Analyze Arc Flash Risks?

To control arc flash hazards effectively, I first need to understand the level of risk present in my facility's electrical system. This involves:

1. Conducting a Detailed Arc Flash Risk Assessment

A detailed arc flash risk assessment must be carried out by qualified engineers as per IEEE 1584. This gives an accurate calculation of the available arc flash incident energy at different parts of the electrical system.

Key factors evaluated are - system voltage, power levels, short circuit currents, conductor spacing, etc. Detailed arc flash labels are then affixed on equipment to indicate the arc flash boundaries and required PPE.

2. Performing Regular Inspections

I need to perform thorough visual inspections of all electrical equipment regularly. This helps identify any potential hazards like damaged insulation, overheating issues, loose connections, etc proactively. Thermography scans also help detect hotspots.

Any problems found must be addressed promptly to prevent future arc flash incidents. Maintenance activities need to strictly follow electrical safety protocols.

3. Analyzing Arc Flash Incident Causes

Whenever an arc flash incident occurs, a detailed incident investigation must be carried out. The root causes like equipment failure, human error, etc. need to be identified and corrected. This ensures similar incidents can be prevented in future.

How to Control Arc Flash Hazards?

Now let us understand the key elements involved in effectively controlling arc flash risks:

1. Follow the NFPA 70E Standard

The NFPA 70E standard provides comprehensive guidelines on electrical safety requirements for employee protection. Some major aspects covered include:

- Establishing an electrically safe work condition - This involves de-energizing equipment and properly grounding it before any maintenance task.

- Use of personal protective equipment (PPE) - PPE like arc-rated clothing, face shields, insulated gloves etc. must be worn by workers based on arc flash risk level.

- Proper tools & equipment - Insulated tools, voltage detectors, arc flash suit hoods etc. need to be provided.

- Adequate training - Employees must be trained to understand arc flash risks and follow safety protocols.

Strict compliance with NFPA 70E is crucial to create an electrically safe working environment. A written electrical safety program that covers the key elements of NFPA 70E requirements must be implemented.

2. Engineering Controls

Several engineering controls can help minimize arc flash risks:

- Use of current limiting fuses, arc resistant switchgear, and circuit breakers to limit the arc flash incident energy.

- Increased working clearance between conductors and electrical equipment.

- Barriers, insulated covers, and arc flash suit hoods provide added protection during maintenance tasks.

- Arc flash detection systems can also quickly detect arcs and trigger system shutdown.

3. Administrative Controls

Implementing good administrative controls is key:

- Only qualified personnel should operate or maintain electrical equipment after proper training.

- Standard safety operating procedures should be established for all workers.

- Regular inspection and maintenance programs must be implemented.

- Ensure proper labelling of arc flash hazards on equipment.

- Always follow lockout/tagout procedures for isolation.

- Maintain accident reports and conduct incident investigations.

Effective administrative controls and work practices ensure that arc flash risks are minimized over the long run.

Real-World Example

Let me give a real-world example to illustrate the importance of arc flash control:

An automotive plant was experiencing recurrent arc flash incidents during maintenance work. 3 technicians had been injured in the last year alone. An external consultant was brought in to conduct a detailed arc flash risk assessment.

Several issues were identified - lack of proper PPE, inadequate working space around energized equipment, and absence of strict safety protocols. Corrective actions were recommended like purchasing arc-rated PPE sets, increasing working clearances, implementing a written electrical safety program, and retraining workers.

These measures were implemented correctly by the plant management. Over the next year, the number of arc flash incidents reduced significantly. The plant was able to dramatically improve its electrical safety record and avoid further injuries.

This example demonstrates that a structured approach combining risk assessment, engineering controls, administrative controls, PPE use, and retraining can successfully control arc flash hazards.

Conclusion

Preventing arc flash injuries requires continuous vigilance and effort. As an industrial facility manager, I must implement a comprehensive electrical safety program that covers regular assessment, maintenance, engineered controls, safe work practices, training, and proper arc-rated PPE.

Staying up-to-date with the latest NFPA 70E requirements and investing in the protection of my employees are key to controlling arc flash risks. This obscure guide has provided me with extensive knowledge on evaluating arc flash hazards and implementing appropriate safeguards. Applying these learnings can help create an electrically safe workplace.