How to Safely Splice Old Knob and Tube Wiring

Introduction

Working with old knob and tube wiring can be dangerous if you don't take the proper safety precautions. As the homeowner, I have a responsibility to myself and my family to ensure any electrical work I do is done safely. In this article, I will provide a comprehensive guide on how to safely splice old knob and tube wiring, covering key safety tips and recommended materials and methods. My goal is to enable you to update your antiquated electrical system while avoiding hazards like shock, fire, and electrocution.

Understanding Knob and Tube Wiring

Before splicing into old knob and tube wiring, it's important to understand what you're working with. This early form of electrical wiring was used in homes up until the 1940s. It features:

- Ceramic knobs that hold the wiring off surfaces

- Tubes that protect wires through open spaces

- Two or more wires, usually ungrounded

- Cloth or rubber insulation around wires

Key safety risks with knob and tube wiring include:

- No grounding - can lead to shocks and make it unsafe for modern appliances

- Overloaded circuits - old wiring wasn't designed for modern electricity usage

- Exposed wires - insulation often deteriorates over time

I recommend having a professional inspect your knob and tube wiring before doing any work. They can assess conditions and determine if any parts should be replaced.

Safety Gear and Materials

Splicing into old wiring can be hazardous. Before I start any electrical project, I make sure to have:

Safety Gear

- Insulated gloves - protect against shocks

- Safety goggles - prevent injuries from sparks or debris

- Dust mask - avoid breathing in old insulation particles

Materials

- Junction box - encloses splice connections

- Wire nuts - secure wires together in junction box

- Electrical tape - insulate wires and connections

- Cable clamps - secure cables entering junction box

I avoid using electrical tape alone without wire nuts - this can loosen over time. I also steer clear of twisting wires together without a junction box. All splices must be contained.

Step-by-Step Guide to Splicing Knob and Tube Wiring

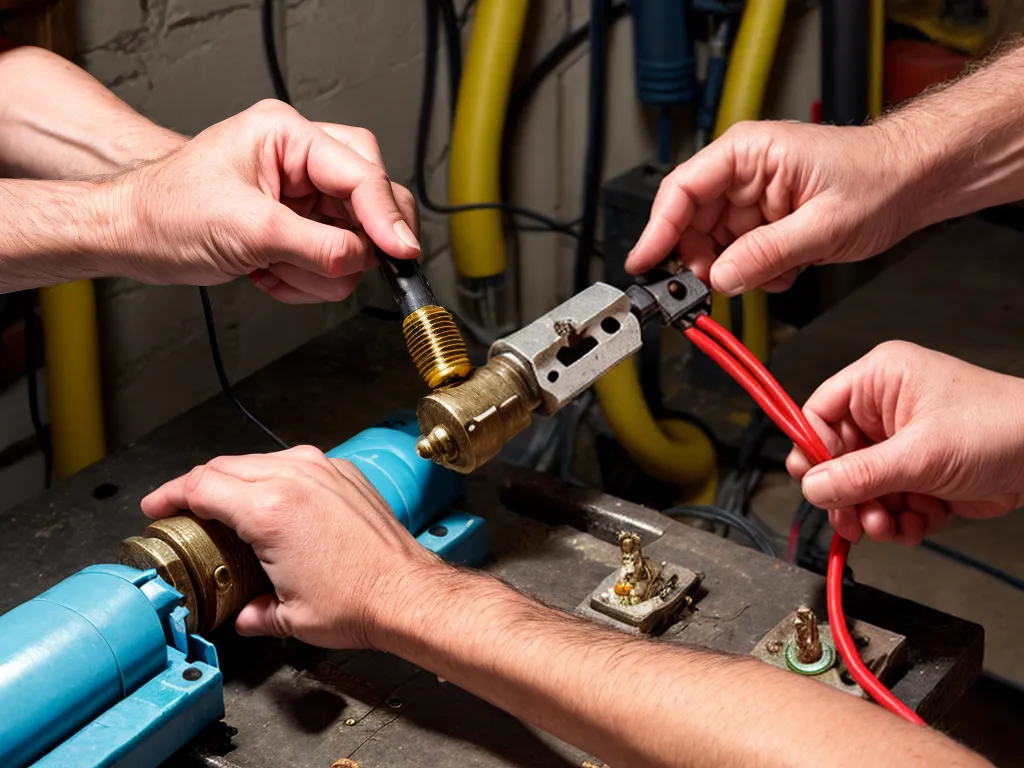

With the right safety gear and materials, you can safely splice into knob and tube wiring:

Step 1: Turn Off Power

Before doing any work, I flip the main breaker switch and unplug any appliances on the circuit I'll be splicing into. I also turn off power with the individual fuse or breaker for that circuit. I always double check with a non-contact voltage tester.

Step 2: Access the Wires

I carefully remove any knob and tube wiring from ceramic knobs or tubes near the splice point. If the wiring is brittle or cracked, I call in an electrician to replace it.

Step 3: Prepare the Wires

I strip about 1/2 inch of insulation off each wire I'm splicing, being careful not to nick the copper. I twist the copper wires tightly together with pliers and apply insulating electrical tape.

Step 4: Install Junction Box

I mount a junction box at the splice location, following instructions to find proper mounting points. I feed the spliced wires through the cable clamps into the box.

Step 5: Make Connections

I twist a wire nut onto each wire connection point, securing the bare copper wires together. I tug gently on wires to ensure a tight connection.

Step 6: Secure Wires

I spread out the wires attached to each terminal inside the junction box so there are no loose wires. I tighten cable clamps and attach the junction box cover.

Step 7: Restore Power and Test

Once the splice is fully enclosed, I turn power back on at the main breaker and circuit breaker/fuse. I test outlets on the circuit with a voltage tester.

I avoid overloading the circuit by plugging in too many appliances, and I plan to upgrade the wiring over time.

Summary

Splicing old knob and tube wiring brings serious safety risks. With the right materials, protective gear, precautions, and testing, you can complete this project safely. If at any point you don't feel comfortable, I strongly advise calling a licensed electrician. Your safety is paramount when dealing with outdated electrical systems.