Installing your own electrical wiring can seem like a daunting task, but with the right preparation and safety precautions, it can also be a great way to save money on your next renovation or new construction project. As an avid DIYer and homeowner looking to cut costs, I found that with careful planning and attention to detail, I was able to safely install new electrical circuits and wiring in my home.

Researching Electrical Codes and Getting Necessary Permits

The first step in any electrical project is understanding the local and national electrical codes that apply to your area. I consulted my local jurisdiction's website to find the adopted electrical code, which provided key information on required wiring sizes, outlet and junction box fill limits, required GFCI and AFCI protections, and more. I also researched national electrical codes like the NEC for additional details.

Knowing the code requirements helped me plan my wiring project to meet the minimum standards. I also made sure to pull all necessary permits before starting, which most jurisdictions require for any significant electrical work. This ensured my work would be inspected for safety. The permit office was also helpful for answering questions I had throughout the process.

Choosing the Right Wire Size and Type

Choosing the appropriate wire size and type for your needs is critical for safety and proper functionality. I used the NEC requirements for minimum wire sizes based on the circuit amperage and voltage. For standard 15A and 20A 120V branch circuits, I used 12 AWG and 14 AWG copper wiring respectively. I also chose quality THHN/THWN-2 wire with stranded conductors for flexibility and ease of installation.

For circuits with larger loads like electric water heaters and AC units, I opted for 10 AWG wire as required by the code. I also used UF-B wire rated for direct underground burial when wiring detached garages and outbuildings. Carefully selecting the correct wire drastically reduces the risk of fires from undersized conductors.

Using Proper Tools and Safety Equipment

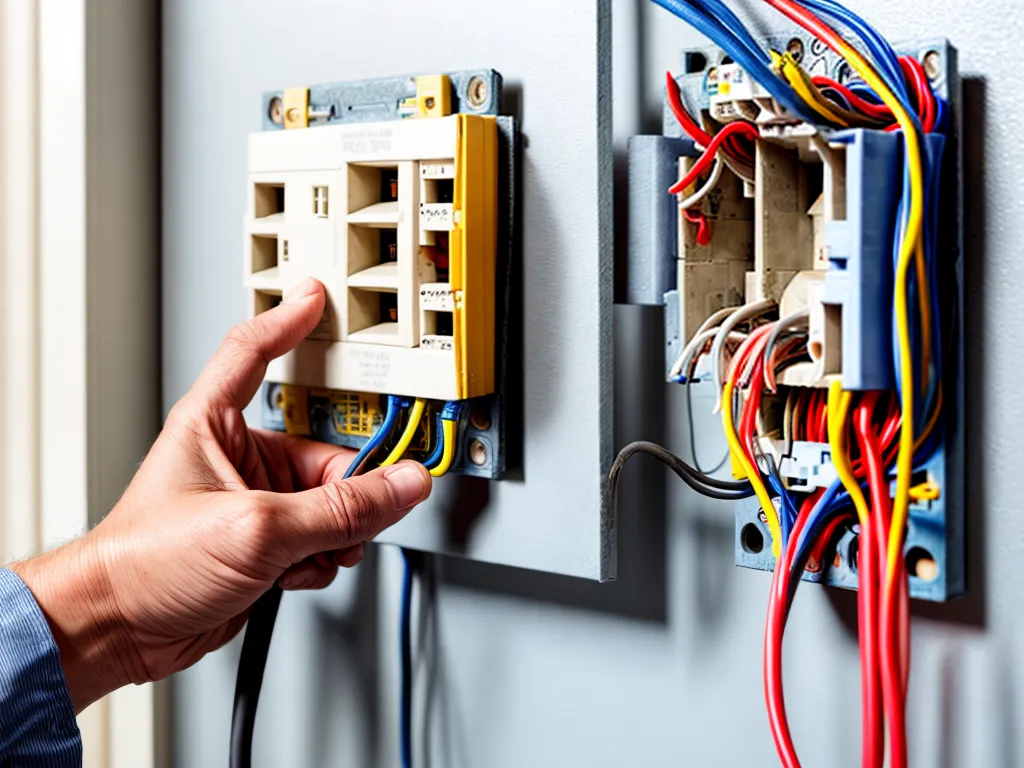

Installing home electrical wiring requires specialized tools for cutting, stripping, and joining wires. I invested in a quality wire stripper, linesman pliers, a voltage tester, and a clamp style ammeter to safely measure current. I also gathered necessary safety equipment like electrical gloves, glasses, and arc flash protective clothing for working on live circuits.

For cutting holes through studs and joists for running wiring, I used a multi-tool for precision and safety. I avoided attempting electrical work without the right tools, proper PPE, and basic electrical knowledge, as mistakes can be fatal. Ensure you are prepared before taking on complex tasks like installing circuit breakers and connecting wires to outlets and switches.

Planning Circuits and Installation Locations

Careful planning is essential for installing wiring efficiently and correctly on the first try. I created detailed circuit diagrams showing all outlet, switch, and lighting locations with expected voltages and wire runs. I grouped rooms and areas with similar needs on shared circuits to avoid overloading any one circuit.

I also strategically planned outlet placement based on anticipated furniture layouts and device usage. Code-approved junction boxes were included at necessary splice and transition points. Planning the circuits ahead of time made the actual wiring process smoother.

Running and Securing Wires Safely

I was careful to run wiring in code-approved locations and avoid potential hazards. Wires inside walls were properly supported every 4.5 ft as required, using metal stud clips or running boards horizontally across studs and joists. Cables were run through holes drilled at least 1.25 inches back from the face of the framing.

For exposed runs like subpanels and outdoor wiring, I used metal conduit for protection. Wires were pulled taught with as few splices as possible. I used cable staples, nylon zip ties, and insulated wire nuts for secure connections. Taking the time to run and fasten the wiring properly reduces the risk of damage.

Connecting Switches, Outlets, and Lights

One of the most rewarding parts of installing electrical wiring is seeing the finished product operational. I used the diagrams created earlier to properly connect all wires to switches, outlets, light fixtures, and appliances based on voltage and grounding needs. White wires were connected to silver screw terminals, black to brass or copper.

I made sure to provide a sufficient 6 inch service loop of wire inside boxes for outlet and switch connections to avoid pulling on lugs. Double checking polarity and ground connections ensured proper and safe functionality. I successfully installed overhead lighting, exhaust fans, 240V appliances and more - all up to code.

Getting My Work Inspected and Making Any Required Changes

The final and most crucial step was having all installed wiring and equipment inspected by the local building department. I scheduled this inspection once the work was complete and before concealing any wiring. The thorough inspection uncovered a couple omitted ground connections and improper breaker fill in the panel I was able to immediately fix.

I also had to provide GFCI protection near some plumbing fixtures per the inspector's feedback. After making the required corrections, my wiring installation passed on the second visit. The permit process and inspection gives you valuable feedback and helps ensure safety. I am now confident my home's new electrical system meets all requirements.

While handling home electrical projects on your own requires diligent planning and attention to safety, the potential cost savings are immense. By educating myself on the code, using proper tools, and hiring an inspector, I successfully installed several new circuits and wiring in my home addition that will serve my family for years to come. The sense of accomplishment and thousands saved make the effort worthwhile.