How to Troubleshoot Obscure Electrical Control Panel Issues

Introduction

As an electrician, I often encounter obscure electrical issues that are difficult to diagnose and repair. Electrical control panels can develop problems over time due to component failure, loose connections, or changes made to the system. When an issue crops up that I can't easily identify, I rely on my troubleshooting process and expertise to methodically track down the root cause. In this guide, I'll share my approach for investigating and resolving the most perplexing electrical control panel problems.

Safety First

Before troubleshooting any control panel issue, safety should always be the top priority. Electrical control panels contain high voltage components that can seriously injure or even kill if handled improperly. Here are some key safety precautions I take:

- Use proper personal protective equipment (PPE) like insulated gloves, safety glasses, and flame resistant clothing

- Turn off all power to the control panel before opening or working on any components

- Use a multimeter to verify power is off before touching any parts

- Clearly tag/lock out the control panel to prevent accidental re-energizing

- Check for dangerous stored energy like capacitors that may retain charge

Following safety protocols helps prevent electrical shocks, burns, and other injuries. Rushing into troubleshooting without the proper precautions can have dire consequences.

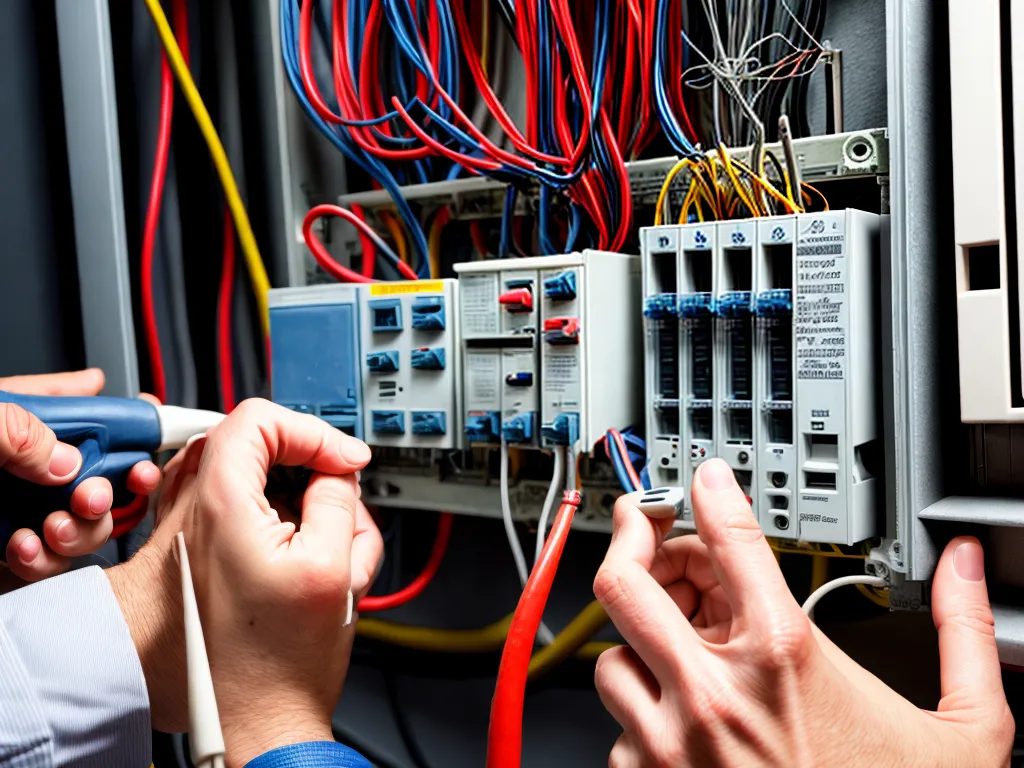

Start with Visual Inspection

My first step when troubleshooting an obscure control panel issue is a thorough visual inspection looking for any outward signs of problems. I check for:

- ** Loose or damaged connections** - Wire terminations can vibrate loose over time. I wiggle connections to check for tightness.

- Discolored or overheated components - Signs of overheating can indicate a faulty component.

- Arcing or burning - Look for darkened areas that may indicate arcing or electrical shorts.

- Cracked insulation - Insulation damage can expose dangerous live voltages.

- Melted wires - Extreme overheating melts wire insulation.

- Blown fuses - Blown fuses reveal which circuit has failed.

- Tripped breakers - Similar to fuses, tripped breakers indicate a faulty circuit path.

- Damaged terminals - Cracked, burned, or broken terminals need replacing.

Carefully examining all wiring, connections, and components can reveal physical defects pointing to the root cause. I may spot an obviously loose connection or burnt component.

Check Error Codes and Indicator Lights

Many control panels have indicator lights that provide diagnostics codes and error messages pointing to problems. I inspect any text displays or flashing indicator lights for clues. For example, a "Fan Failure" error code clearly indicates the cooling fan needs troubleshooting. Or a flashing overload light could signify a motor drawing too much current. Error codes vary by manufacturer but provide a valuable starting point before diving deeper.

Review Control Circuit Operation

To fully diagnose obscure control panel issues, I need an in-depth understanding of the underlying control circuits and operation. Reviewing wiring diagrams, ladder logic programs, data sheets, and manuals provides critical insight. Important areas I focus on include:

- Input circuits - Study how the panel receives control signals to operate loads. Faulty inputs can prevent operation.

- Sequencing and timing - Control logic often follows set sequences that can malfunction.

- Safety interlocks - Look for safety mechanisms like limit switches that may have failed.

- Mode selection - Incorrect mode selection or configuration can cause abnormal operation.

- Outputs - Outputs switching loads may be overloading or shorted.

By thoroughly analyzing control circuitry on paper, I can better pinpoint potential failure points before taking measurements.

Check Power Supply Health

The control panel power supply provides critical voltages to all electronics. I test power supply health by:

- Measuring voltages - Use a multimeter to verify DC and AC voltages match specifications.

- Look for ripple - Excessive ripple indicates poor power regulation.

- Check fusing - Confirm fuses or breakers protecting power circuits are not blown or tripped.

- Connections - Inspect power supply terminal connections for problems.

A weak, unstable, or noisy power supply can lead to all sorts of issues like intermittent failures or component damage.

Take Critical Measurements

With a good understanding of the control panel internals, I begin methodically taking key measurements to isolate the malfunction. I focus on:

- Control signals - Check digital and analog inputs with a multimeter or oscilloscope.

- Load currents - Current probes reveal overloads or greatly asymmetric phases.

- Circuit continuity - Check for open circuits that may have failed.

- Component testing - Directly test individual components like capacitors for out of spec readings.

Comparing measurements against circuit diagrams often reveals deviations pointing to the root cause. I look for both absolute measurement values out of expectation, and relative differences between supposedly symmetric circuit paths.

Employ Specialized Testing Methods

For the most difficult intermittent or temperature-dependent problems, I use special testing techniques to uncover the issue:

- Wiggle testing - Gently flexing wiring and connections can provoke latent faults.

- Thermal imaging - An infrared camera displays hot spots identifying overloaded components.

- Vibration analysis - Sensors can detect bearing wear and electrical noise indicating impending failures.

- Ultrasonic testing - High-frequency sound detection can find arcing or corona discharge.

These methods help diagnose faults that may only manifest under special conditions. I isolate problems that standard troubleshooting approaches may miss.

Refine the Search Area

As I gather more troubleshooting data, I continuously narrow down the search area and refine my working theories on the most likely fault causes. I eliminate certain component types or circuits from consideration when they check out okay. Focusing the diagnosis prevents wasting time barking up the wrong tree. I ask myself probing questions:

- Does the problem occur only under certain conditions?

- Have any changes or repairs been made recently?

- What sequence of events leads up to the malfunction?

- What downstream components may be affected by a faulty section?

Careful troubleshooting is a puzzle-solving exercise that incrementally fills in the big picture.

Seek Help from Experts

For particularly perplexing issues after exhaustive troubleshooting, I may solicite help from technical experts on that control panel or from the manufacturer. With their design knowledge, they may quickly recognize clues that lead me to the root cause. I prepare by documenting:

- Precise sequence of symptoms

- Tests and measurements taken

- Photos and readings showing the malfunction

With detailed information, an expert can usually remotely diagnose the fault. However, I never fully rely on external help and always think through the problem independently first.

Confirm Repairs Fix the Problem

After finally identifying the failure point, I replace or repair the faulty component and verify normal operation is restored. If the problem persists, I recheck repairs and resume troubleshooting. I don't consider the issue fully resolved until operation is restored and I understand exactly why the failure occurred in the first place.

Improve Future Reliability

Beyond just fixing the immediate problem, I try to learn from each troubleshooting experience to improve the control panel's long-term reliability and serviceability:

- Add missing indicator lights to aid future diagnosis

- Improve component accessibility for easier testing

- Tighten loose connections to prevent future intermittency

- Discuss chronic issues with equipment operators

- Recommend design improvements to prevent recurrences

Careful follow-through ensures obscure control panel problems stay fixed, and hopefully don't return.

Summary

Diagnosing obscure electrical control panel issues requires methodical troubleshooting procedures, safety awareness, and strong circuit knowledge. By following a rigorous process of visual inspection, measurement, specialized testing, and expert consultation I can unravel even the most perplexing faults. The solution is always found through diligence and hard-won experience.