Introduction

Wiring a factory to utilize advanced manufacturing techniques like robotics and automation can seem daunting, especially for small businesses with limited budgets. However, with careful planning and phased implementation, going broke doesn't have to be the end result. In this article, I'll walk through step-by-step how a factory manager can thoughtfully wire their facility for innovation without breaking the bank.

Assess CurrentProcesses and Infrastructure

Before making any changes, take stock of current factory processes, equipment, layout, and infrastructure. Map out all existing:

- Manufacturing processes - What products are made, what are the current steps involved, where are potential bottlenecks or inefficiencies?

- Equipment - What machines are used, how old are they, what is their maintenance status?

- Facility layout - How are workstations and inventory organized? Is the flow efficient?

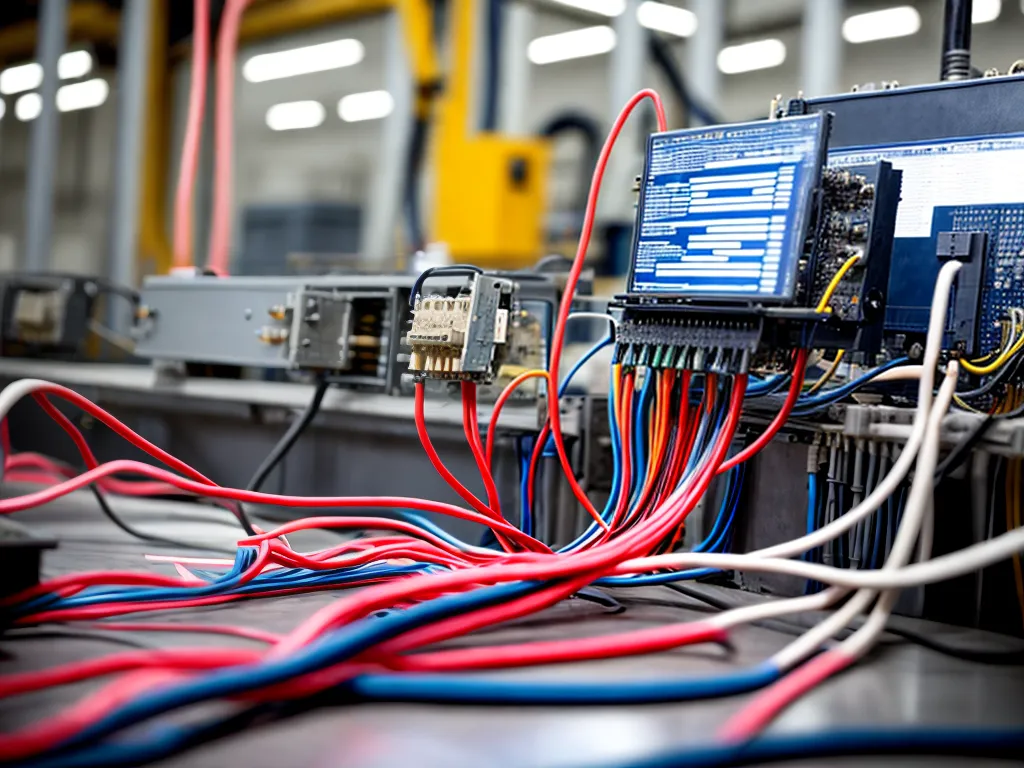

- Infrastructure - What is the status of power, network cabling, servers/computers, lighting, HVAC?

This assessment will identify top priorities for upgrades and optimization.

Create a Phased Plan

With priorities identified, create a phased implementation plan to spread costs over time. Some ideas:

- Phase 1: Infrastructure upgrades like improving wireless networks, servers, and power. These enable future innovation.

- Phase 2: Implement automated inventory management. This frees up staff time later.

- Phase 3: Add robotics to the most labor-intensive processes. Focus on quick ROI.

The key is to stagger big changes instead of overhauling everything at once. Begin with affordable fixes like 5S lean manufacturing to improve workflow.

Evaluate In-House vs Outsourced Options

Carefully weigh make vs buy choices for new technology:

- In-house pros: More control, internalize expertise over time

- Outsource pros: Faster deployment, leverage vendor expertise

A blended approach is often best. For example, use an external company for initial setup and training, but handle ongoing small improvements in-house. Consider outsourcing only a subsection of a production line to start.

Take Advantage of Incentives

Research government and utility incentives to offset costs:

- Grants for workforce training or sustainable manufacturing

- Tax credits for investing in automation or "green" upgrades

- Energy utility rebates for upgrading to more efficient lighting and equipment

Your local Small Business Development Center can inform you about programs specific to your industry and region.

Start with a Pilot

Before rolling out any major changes:

- Start with a small pilot - Choose a subsection, like one product line or workcell. Limit risk.

- Thoroughly test and refine - Work out any kinks before expanding.

- Train staff - Hands-on practice to build skills and confidence. Address concerns.

Gradual launch reduces disruptions to existing production and cashflow.

Monitor Progress and Metrics

Once implemented, closely monitor key metrics to verify improvements:

- Production output - Units produced per hour/day

- Quality - Defect rates

- Labor costs - Employee hours per unit produced

- Sales - Additional revenue capabilities

Continuous monitoring ensures changes are delivering the desired ROI as expected. Tweak as needed.

Conclusion

Bringing coding and automation into a factory takes careful planning, not just throwing money at the latest tech. By starting slowly, leveraging outside resources, and tracking progress, factory managers can wire their operations for innovation without breaking the bank. A phased, disciplined approach is the key to managing costs while positioning for future growth.